Full Potential

The logistical challenge of loading a colossal 4000 tonne component, a crucial part of the world’s largest turret mooring system for Shell’s Prelude FLNG (Floating Liquefied Natural Gas) facility, onto a barge in Dubai demanded an innovative engineering solution. The existing quay wall, however, was not initially designed to bear such a massive load during the load-out process. Constructing a purpose-built facility tailored to handle the specific operation would have incurred exorbitant costs, running into the millions.

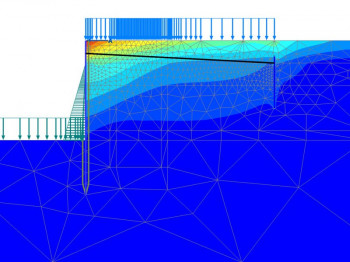

To overcome this dilemma, a comprehensive approach was undertaken. Advanced in situ soil stiffness testing was conducted to ascertain the foundation’s capacity to withstand the load. Coupled with numerical analysis and continuous site monitoring, a detailed understanding of the soil-structure interaction was achieved. This meticulous examination revealed that, contrary to initial concerns, the load-out operation could proceed without the need for structural modifications to the quay wall. The successful execution of this complex manoeuvre, highlighted by coverage on BBC News, not only showcased the capability of innovative engineering solutions but also translated into substantial cost savings for the client, underscoring the efficiency of advanced testing and analysis techniques in optimising large-scale industrial operations.

Highlights

-

Seismic downhole surveys through calcareous sand fill to establish reliable stiffness parameters.

-

Simulation of load-out in FEA model of quay wall.

-

Settlement monitoring during load-out to validate FEA model.

-

Recommendation to allow load-out without structural modifications, saving significant time and cost.